Connect all your manufacture data

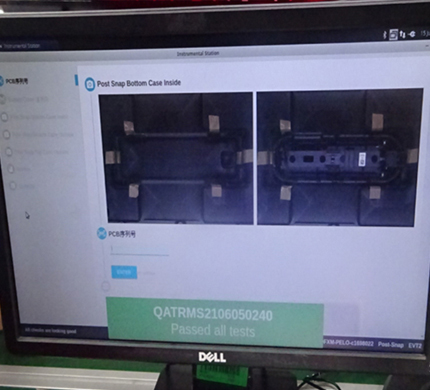

Gather visual and parametric data from cameras, test stations, or Instrumental Stations into a traceable data record for all your units from FATP , final assembly.

Improve Quality and Yield in NPI Programs

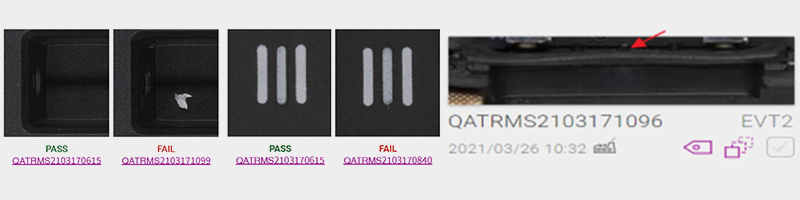

For engineering teams in their NPI Stage, dealing with complex electronics assembly , Aggregate all data, find defects using AI, and accelerate failure analysis with failure analysis tools.

For operations teams to enhance yield, prevent field failures. Get real-time oversight of production line, intercept defective units using visual inspection, get alerts when yield drifts, and conduct faster failure analysis when issues arise.