首页 / Electronic Products / 案例经验分享

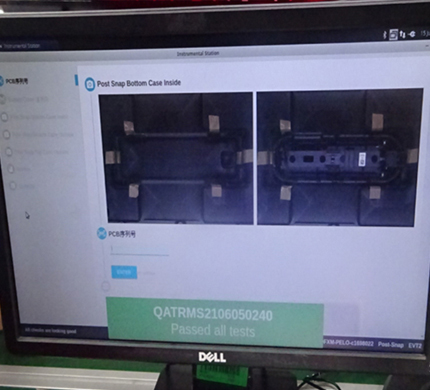

Gather visual and parametric data from cameras, test stations, or Instrumental Stations into a traceable data record for all your units from FATP , final assembly.

For engineering teams in their NPI Stage, dealing with complex electronics assembly , Aggregate all data, find defects using AI, and accelerate failure analysis with failure analysis tools. For operations teams to enhance yield, prevent field failures. Get real-time oversight of production line, intercept defective units using visual inspection, get alerts when yield drifts, and conduct faster failure analysis when issues arise.

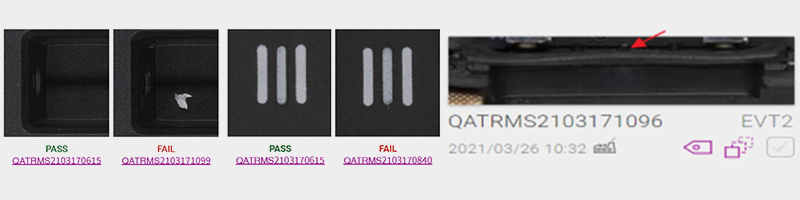

Identify previously unknown defects by using anomaly-detecting AI that can spot differences in units. Turn those into live pass/fail tests on your assembly line and catch every defective unit before they reach the field.

Take actions based on top failing parametric tests and defects. Identify tests and monitor with failed units to keep your processes stable. And for any failing test, quickly dive into failure analysis workflow IN NPI Stage.

Solve problems faster by reviewing potential root causes from visual and data correlations and tracing the problem to its root cause using a historical assembly data record.

We provide the best experience for our customers and the traceable platform.

Prevent field quality issues

Improve yield

Prevent returns

Ramp faster